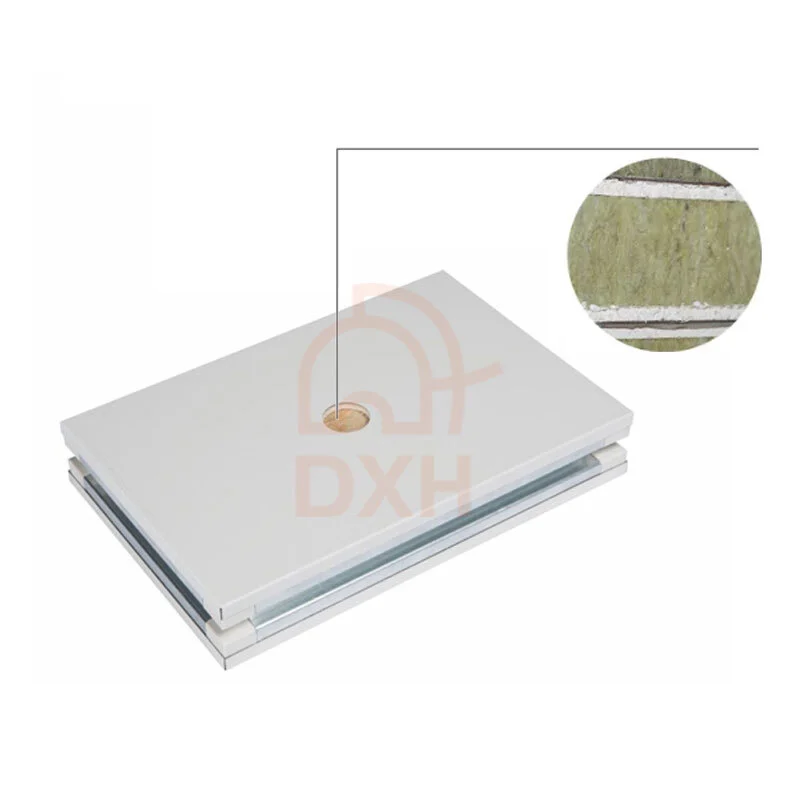

Handmade Glass Magnesium Rock Wool Sandwich Panel

Specifications

|

Core Material |

Glass Magnesium + Rock Wool |

|

Thickness |

50mm, 55mm, 60mm, 75mm, 100mm |

|

Width |

900mm, 980mm, 1150mm, 1180mm. Non-standard panels in any width. |

|

Length |

Custom manufacturing is available upon request (general length ≤ 6000mm). |

|

Panel Thickness |

0.4~0.6mm |

|

Thermal Resistance |

1.8 kcal/m²·h·°C |

|

Outer Facing |

Typically color-coated steel, galvanized steel, or stainless steel |

|

Edge Sealing |

Perimeter encapsulation using aluminum profiles, galvanized steel, or PVC profiles. |

|

Connection Type |

Tongue-and-groove or concealed cam-lock (handmade flexibility) |

|

Bonding Agent |

Non-toxic, eco-friendly polyurethane adhesive or modified epoxy adhesive. |

|

The double glass magnesium rock wool sandwich panels combine thermal insulation and fire resistance, with edges or surfaces finished in sealed or decorative materials. They are designed to provide lightweight, fire-resistant, and thermally insulated enclosure components for walls, roofs, and clean room interiors. |

|

Features and Benefits of Handmade Glass-Magnesium Rock Wool Sandwich Panels

Fire Resistance: Class A fire rating, utilizing non-combustible rock wool core and glass-magnesium panels to provide 1-3 hours of fire integrity. The rock wool core typically enhances fire resistance, while the magnesium oxide panels reinforce rigidity and dimensional stability.

Thermal & Acoustic Insulation: Low thermal conductivity (0.043-0.056 W/m·K) minimizes heat transfer, ensuring energy-efficient temperature control. Noise reduction up to 30 dB makes it ideal for noisy environments like train stations and KTV venues.

High Load-Bearing Capacity: The "handmade" process utilizing internally galvanized and high-strength adhesives endows the panels with exceptional rigidity. Ensures reliable installation and performance for roof or wall components.

Moisture-Resistant Hygienic: Waterproof glass-reinforced magnesium alloy prevents warping, mold, or rot. Antibacterial, dust-proof, and anti-static properties create a clean environment.

Eco-Friendly Durable: Constructed from non-toxic, odorless materials with extended service life. Prefabricated structure facilitates easy maintenance and recyclability.

Prefabricated Modular Design: Products are supplied as complete prefabricated modules. Rapid assembly reduces labor and construction time by up to 50%. The modular design facilitates disassembly and reconfiguration.

These panels combine thermal insulation and fire resistance, with edges or surfaces finished in sealed or decorative materials. They are designed to provide lightweight, fire-resistant, and thermally insulated enclosure components for walls, roofs, and cleanroom interiors.

Handmade Glass Magnesium Rock Wool Sandwich Panels: Common Applications

Clean Rooms: Widely used for walls and ceilings in pharmaceutical, microelectronics, and food processing facilities (GMP compliant).

Hospitals and Operating Rooms: Meet stringent requirements for hygiene, fire resistance, and structural integrity.

Industrial Firewalls: Used for fire partitions and enclosures in manufacturing plants and warehouses.

Data Centers and Laboratories: Require high-density insulation and immediate fire protection for sensitive equipment.

Soundproof Enclosures: Ideal for machinery rooms, grinding rooms, broadcast/TV studios, and conference halls with extreme noise control requirements.

Modular and Prefabricated Buildings: Suitable for rapid construction projects requiring durable, high-specification exterior walls.

Ready to elevate your project? Contact us for samples, quotes, or design consultations. Build safer, smarter, and greener structures with handcrafted glass-magnesium rock wool sandwich panels!

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China