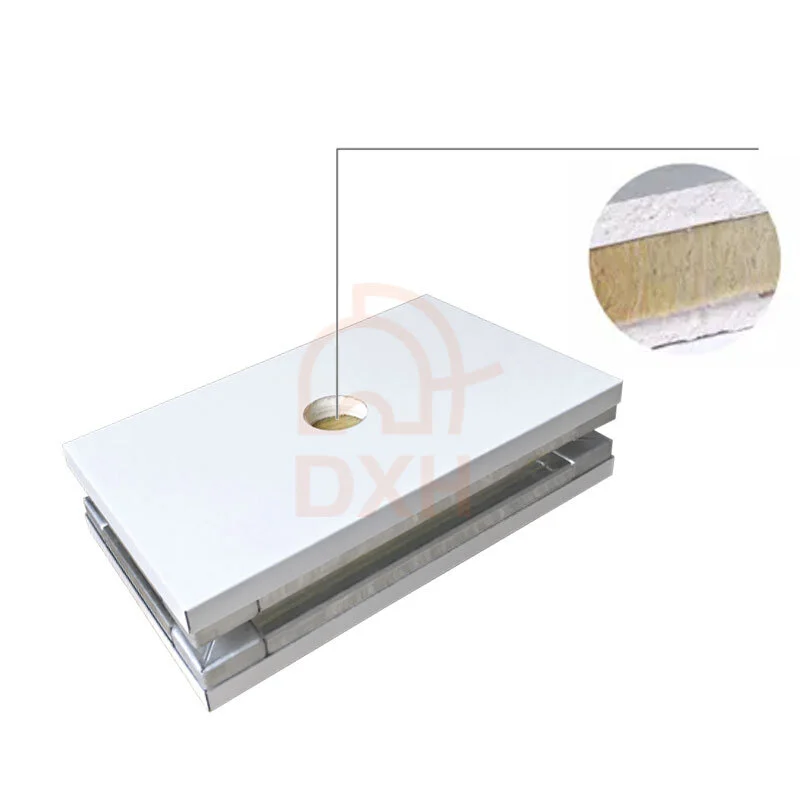

Handmade Gypsum Rockwool Sandwich Panel

Specifications

|

Core Material |

Rock Wool |

|

Thickness |

50mm, 55mm, 60mm, 75mm, 100mm |

|

Width |

900mm, 980mm, 1150mm, 1180mm. Non-standard panels in any width. |

|

Length |

Custom manufacturing is available upon request (general length ≤ 6000mm). |

|

Thermal Conductivity |

0.035~0.045W/m·K |

|

Facings |

Can be color-coated steel, galvanized steel, stainless steel, or gypsum board. |

|

Auxiliary Structural Layer |

Typically equipped with embedded galvanized steel strips or aluminum alloy keel. |

|

Adhesive Layer |

Uses an environmentally friendly, high-strength adhesive. |

|

Edge Sealing |

All four sides are sealed with aluminum profiles or galvanized steel sheets. |

|

Handmade Gypsum Rockwool Sandwich Panel is a high-tech building material that blends the fire safety of rockwool with the smooth finish and ease of gypsum, engineered for demanding, clean, and fire-safe construction. |

|

Advantages of Handmade Gypsum Rock Wool Sandwich Panels

Class A Fire Resistance: Rock wool material is a Class A non-combustible material that does not burn, melt, or release toxic fumes when exposed to fire. Combined with the flame-retardant properties of gypsum boards, it meets construction requirements for over one hour of fire resistance.

Thermal Insulation: Rock wool's low thermal conductivity provides excellent insulation within the sandwich panel, reducing energy consumption and enhancing energy efficiency.

High Strength and Stability: Hand-made gypsum rock wool sandwich panels incorporate a metal skeleton combined with high-strength adhesive bonding, delivering outstanding structural stability. They are suitable for high-load applications such as tall partitions and large-span ceilings.

Sound Absorption and Noise Reduction: The rock wool core exhibits outstanding acoustic absorption properties, effectively dampening mid-to-high frequency noise. This makes it suitable for noise-sensitive environments, such as cleanrooms and laboratories.

Environmentally Friendly and Easy to Install: Both gypsum and rock wool are non-toxic and eco-friendly, meeting the standards of green buildings. The manual panel manufacturing process offers high adaptability, allowing for prefabrication to exact dimensions and rapid on-site assembly, significantly improving construction efficiency.

Moisture-Resistant and Mold-Proof: Both gypsum panels and rock wool cores offer strong moisture resistance. When paired with edge sealing, they effectively withstand high-humidity environments or meet stringent cleanroom standards, preventing mold growth and corrosion.

Clean and Aesthetic: Featuring a smooth, attractive surface typically finished with gypsum, these panels are highly suitable for sterile/clean environments (e.g., pharmaceutical and electronics industries).

Installation Guide for Hand-made Gypsum Rockwool Sandwich Panels

During installation, these gypsum rockwool sandwich panels support flexible configurations. Common methods include:

Vertical Partition Installation: Secure panels using U-shaped floor tracks and C-shaped studs. Aluminum alloy edge trims at top/bottom joints ensure overall flatness and sealing.

Ceiling System Construction: Panels are suspended from T-shaped ceiling tracks to form a stable, clean ceiling system.

Removable Structure Design: Facilitates future maintenance and equipment replacement by incorporating removable cover plates for easy access and disassembly.

Installation Key Points

Panels must be stored in a dry, well-ventilated environment to prevent moisture exposure.

Avoid throwing or dropping panels during handling to prevent edge damage.

Apply sealing strips to all joints to eliminate particle leakage.

Perform cleanroom processing after installation to ensure dust-free conditions before use.

In summary, DXH Container House's handmade gypsum rock wool sandwich panels provide a perfect solution for interior applications. With its smooth finish, superior sound and thermal insulation, impact resistance, and fireproof properties, this product stands as a reliable and versatile choice for any construction project.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China