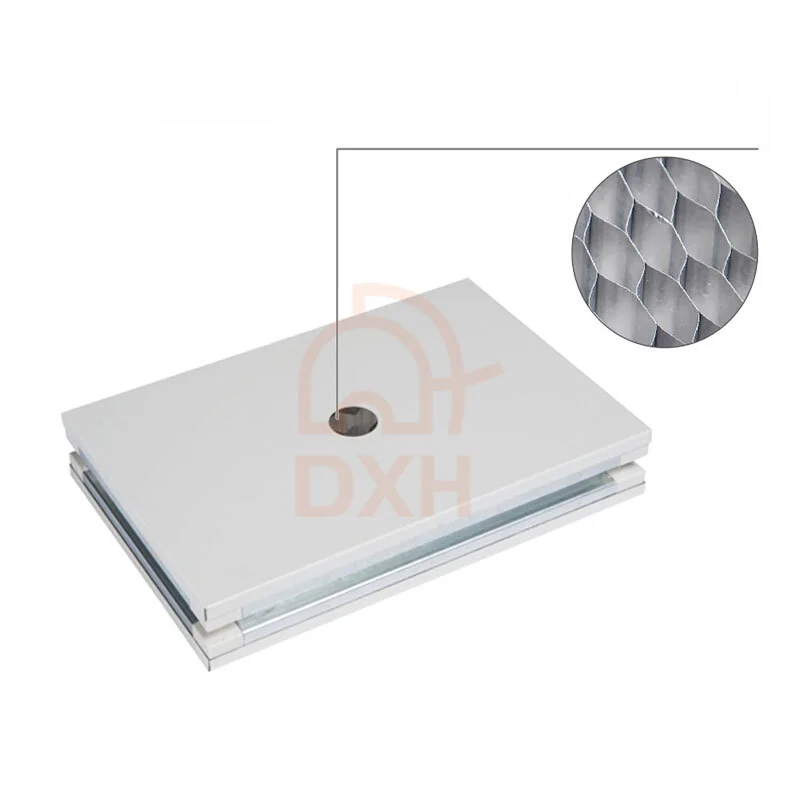

Handmade Aluminum Honeycomb Sandwich Panel

Specifications

|

Core Material |

Aluminum Honeycomb |

|

Core Cell Size |

5mm~10mm |

|

Thickness |

50mm, 75mm, 100mm |

|

Width |

960/980mm, 1160/1180mm |

|

Length |

Customized to meet specific needs (generally ≤6000mm) |

|

Panel Thickness |

0.5mm–1.2mm aluminum alloy panels (3003 or 5052 grades available) |

|

Edge Sealing |

Use aluminum profiles, galvanized steel, or stainless steel U-channels for edge encapsulation |

|

Connection Type |

Tongue-and-groove or concealed cam-lock (handmade flexibility) |

|

Adhesive |

Specialized aerospace-grade or eco-friendly polyurethane adhesive |

|

Featuring a unique hexagonal core structure, this aluminum honeycomb sandwich panel offers high compressive strength, excellent tensile properties, and lightweight characteristics, qualifying it as an eco-friendly building material. Its appealing design and functional performance make it a preferred choice for engineering projects in medical cleanrooms, electronics manufacturing facilities, building exteriors, rail transit, aerospace, and marine applications. |

|

Advantages of Handmade Aluminum Honeycomb Sandwich Panels

Lightweight Strength: The honeycomb structure offers low density yet exceptional compressive and flexural strength. Weighing only 1/5 to 1/10 of solid panels of equivalent thickness, which reduces building structural load.

Corrosion and Oxidation Resistance: Excellent weather resistance and corrosion protection, suitable for humid environments and high-salt conditions.

Easy Cleaning and Maintenance: With smooth surfaces or coatings (anodized, polyester baked paint, or fluorocarbon spray treatment), which resist dust accumulation. Daily maintenance can be done using cleaning agents such as alcohol, water, or disinfectants.

Fire Resistance: Aluminum alloy and aluminum cores are non-combustible materials, achieving a Class A2 fire rating. This meets fire safety standards for most building and industrial projects.

Thermal and Acoustic Insulation: The air chamber structure within the honeycomb core blocks sound waves and heat flow transmission, effectively reducing ambient noise and enhancing energy efficiency management.

Customizable: Tailored to your specific requirements, including custom dimensions, colors, and installation methods. Panels can be perforated, cut, or bent to accommodate diverse design and structural needs.

Installation Guidelines for Handmade Aluminum Honeycomb Sandwich Panels

To ensure optimal performance of aluminum honeycomb sandwich panels, observe the following during installation:

Installation Benchmarks: Level the floor, walls, and ceiling reference points to enhance joint precision.

Edge Sealing: Apply sealant and pressure strips properly to prevent air infiltration and maintain cleanliness.

Lifting Method Compatibility: Use compatible framing or specialized mounting hardware to ensure panel stability and prevent deformation.

Clean Site Operations: Minimize cutting dust dispersion during construction to preserve final cleanliness standards.

At DXH Container, we combine traditional craftsmanship with advanced materials to produce panels that outperform machine-made panels. Our aluminum honeycomb panels avoid common flaws seen in mass-produced sheets. They also offer benefits like improved flatness and edge stability, fewer voids, and consistent performance.

Order aluminum honeycomb sandwich panels today to enhance the quality of your project.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China