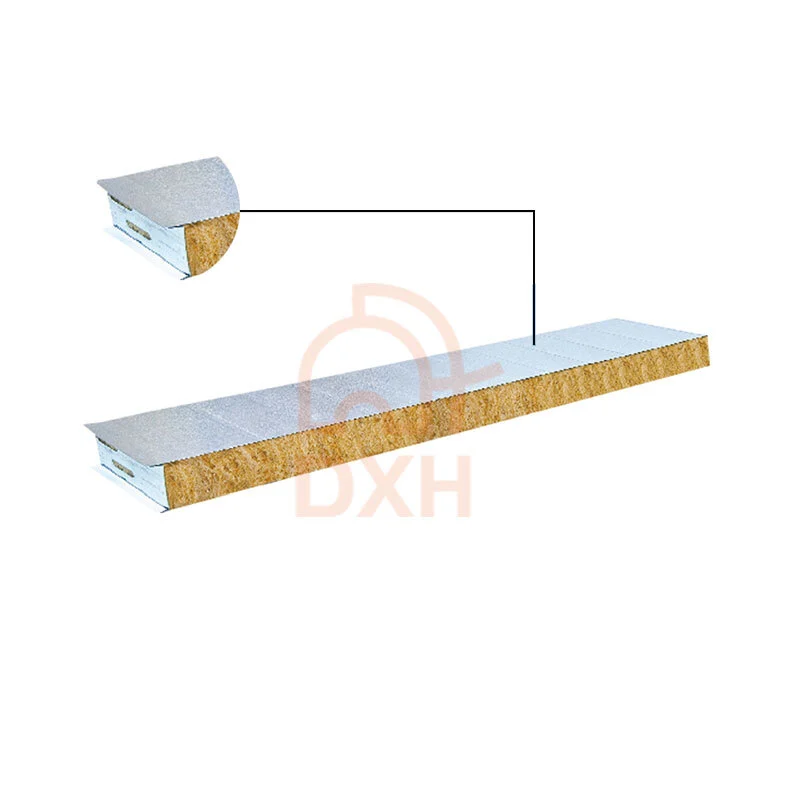

Oven Rock Wool Sandwich Panel

Specifications and Properties

|

Width |

950mm, 1150mm |

|

Length |

Customized according to project requirements and transportation conditions |

|

Core Material |

Rock Wool |

|

Thickness |

50mm, 75mm, 100mm, 150mm |

|

Core Density |

Ranges from 80 to 150 kg/m³ |

|

Thermal Conductivity |

Around 0.035 W/m·K, providing effective insulation |

|

Fire Resistance |

Class A |

|

Composition of Panel |

Color-coated steel, galvanized or stainless steel |

|

Shape / Profile |

H-panels (flat panels, profiled panels), tongue-and-groove panels, corrugated panels |

|

Color |

Select according to project requirements |

Oven Rockwool Sandwich Panel Advantages

Oven rockwool sandwich panels offer significant advantages for use in drying tunnels, particularly in oven applications. Here are some key benefits:

High-Temperature Resistance: Rockwool can endure extremely high temperatures, exceeding 650°C, without melting. This makes it an excellent choice for ovens and other industrial applications.

Effective Thermal Insulation: The core of rock wool has low thermal conductivity, which helps block heat transfer and reduces heat loss. Using these panels can lead to lower energy consumption in drying equipment, improving thermal efficiency, and providing energy savings and emission reductions.

Fire Safety: Being an inorganic non-combustible material, rock wool meets national Class A fire safety standards. It does not burn or emit harmful fumes at high temperatures, which significantly boosts fire safety for equipment and facilities.

Durability and Longevity: Dryer Oven Rock Wool Sandwich Panels are robust and durable, with impact resistance and corrosion resistance. The dense rock wool core is resistant to deformation, ensuring a long service life and reduced maintenance costs.

Lightweight and Easy Installation: Compared to traditional materials such as bricks and foams, rockwool panels are lightweight, making them easier to transport and install. This makes quicker construction, helping to shorten project timelines.

Eco-Friendly Compliance: Rockwool is non-toxic, odorless, and free from harmful volatile substances, making it environmentally friendly. It meets the standards for modern green buildings, which is especially beneficial in industries with stringent cleanliness requirements, such as food processing and pharmaceuticals.

Noise Reduction: The porous design of rockwool panels helps absorb sound, minimizing mechanical noise during oven tunnel operations and enhancing the overall workshop environment.

These benefits clearly demonstrate why oven rock wool sandwich panels are an ideal choice for improving the efficiency and safety of drying tunnels.

Applications of Oven Rock Wool Sandwich Panels

Electronic Component Drying: After soldering, electronic components need quick drying and curing in drying tunnels. Oven rock wool sandwich panels provide excellent thermal insulation, minimizing heat loss and ensuring stable processing conditions.

Food Drying and Dehydration: When drying fruits, vegetables, nuts, and meat, drying tunnels equipped with rock wool sandwich panels maintain consistent temperatures, ensuring food quality while improving energy efficiency.

Automotive Coating Curing: High temperatures are typical in automotive coating tunnels. Rock wool sandwich panels are designed to withstand extreme heat, enhancing fire resistance and overall energy efficiency.

Pharmaceutical and Medical Applications: Sandwich panels featuring a rock wool core offer excellent thermal insulation and fire resistance for roofs and walls in the pharmaceutical industry. Moreover, these panels are eco-friendly and non-toxic, ensuring compliance with GMP standards.

Textile Drying: In textile manufacturing, drying tunnels need to remove moisture quickly and consistently. The superior thermal properties of rock wool sandwich panels allow for more efficient heat utilization.

Industrial Furnaces and Heat Treatment: Such as heat treatment and annealing furnaces, require high-temperature equipment. The dryer oven rockwool sandwich panels provide effective insulation, ensuring safe and efficient operation

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China