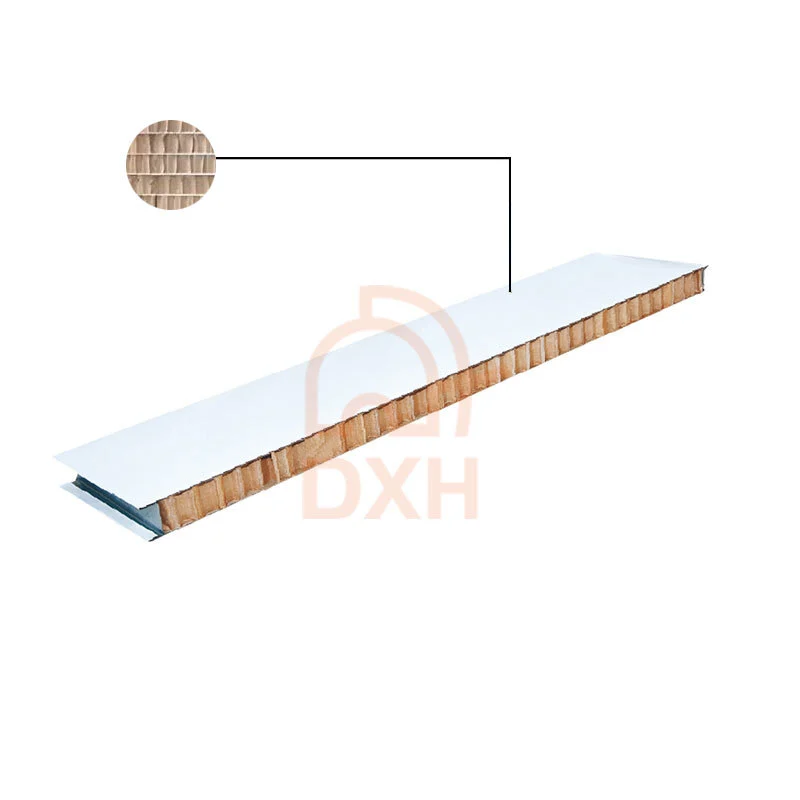

Paper Honeycomb Sandwich Panel

Paper honeycomb sandwich panels are lightweight composite panels formed by thermally or cold-pressed bonding. They feature a honeycomb-shaped paper core as the core material, covered on both sides with plywood, cardboard, gypsum board, galvanized iron sheet, or other composite facing materials.

The internal honeycomb structure mimics the shape of natural honeycombs, providing excellent load-bearing and compressive strength. Being primarily made from paper—a recyclable and biodegradable material—it represents a genuinely eco-friendly product.

Specifications and Properties

|

Width |

950mm, 1150mm |

|

Length |

Customized according to project requirements and transportation conditions |

|

Core Material |

Non-combustible Paper Honeycomb Foam |

|

Thickness |

50mm, 75mm, 100mm, 150mm, 200mm |

|

Compressional Strengths |

Up to 7 kg/cm² are achievable |

|

Weight Reference |

10kg/m² |

|

Panel Profiles |

H-panels (flat and profiled), tongue-and-groove, and corrugated panels |

|

Color |

Select according to project requirements |

Performance Advantages of Paper Honeycomb Sandwich Panels

The upper and lower panels of paper honeycomb sandwich panels can be made from a variety of materials, such as plywood, medium-density fiberboard, fireproof board, aluminum alloy board, and cardboard, depending on the application.

High Renewable Resource Utilization: Paper honeycomb sandwich panels utilize paper as the primary material, making them recyclable and biodegradable. Their production process generates minimal pollution and a low carbon footprint, fully meeting the standards for green building materials.

Lightweight and Easy to Install: The core paper honeycomb structure of the panel is filled with hexagonal air cells, resulting in extremely low density and reduced weight. This substantially lowers transportation and installation costs, making it particularly suitable for modular buildings and prefabricated construction.

High Strength and Compressive Performance: Honeycomb sandwich panels with a vertical load-bearing capacity, effectively withstanding significant pressure and impact. This makes them an ideal material for packaging, protective applications, and temporary building partitions.

Excellent Thermal and Acoustic Insulation: The sealed air cells within the honeycomb structure provide thermal and sound insulation. Compared to hollow or solid panels, paper honeycomb sandwich panels more effectively block heat transfer and sound propagation, enhancing indoor comfort.

Cost-effective: Due to readily available materials and production processes, paper honeycomb sandwich panels offer a price advantage over other high-performance panels. They are particularly suitable for large-scale temporary structures and budget-conscious space renovation projects.

High Workability and Surface Decorability: Paper honeycomb sandwich panels are easily sawed, slotted, drilled, and decorated. They can suit various styles and facilitate personalized designs. Particularly suitable for interior partition walls, ceiling systems, furniture cabinets, and similar applications.

Primary Application Areas of Paper Honeycomb Core Panels

The thickness and cell size of the paper honeycomb core can be adjusted to suit various applications, resulting in customized panels with varying strengths and applications. These panels are commonly used in the following areas:

Building Interiors: Widely used for interior partitions, ceilings, door cores, and movable partitions. Their lightweight, fire-resistant, and eco-friendly properties make them a preferred material for commercial spaces, office buildings, and residential projects.

Packaging and Logistics Industry: With high strength, light-weight, and cushioning properties, they are an ideal replacement for traditional wooden crates and foam packaging in the transport of export goods, precision instruments, and home appliances.

Furniture Manufacturing Industry: Paper honeycomb sandwich panels prioritize lightweight and eco-friendly solutions, widely used in manufacturing wardrobes, bed bases, partition cabinets, and display racks. They are particularly popular in modular and custom furniture.

Exhibition and Display Sector: Exhibition construction requires lightweight materials and quick assembly/disassembly. Paper honeycomb core panels perfectly meet these requirements for rapid temporary space construction, making them a common material in the exhibition industry.

Prefabricated and Modular Construction: With the backdrop of rapid development in prefabricated construction, paper honeycomb core panels can serve as wall modules, roof panels, and interior panels. This enables factory prefabrication of building materials and rapid on-site assembly.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China