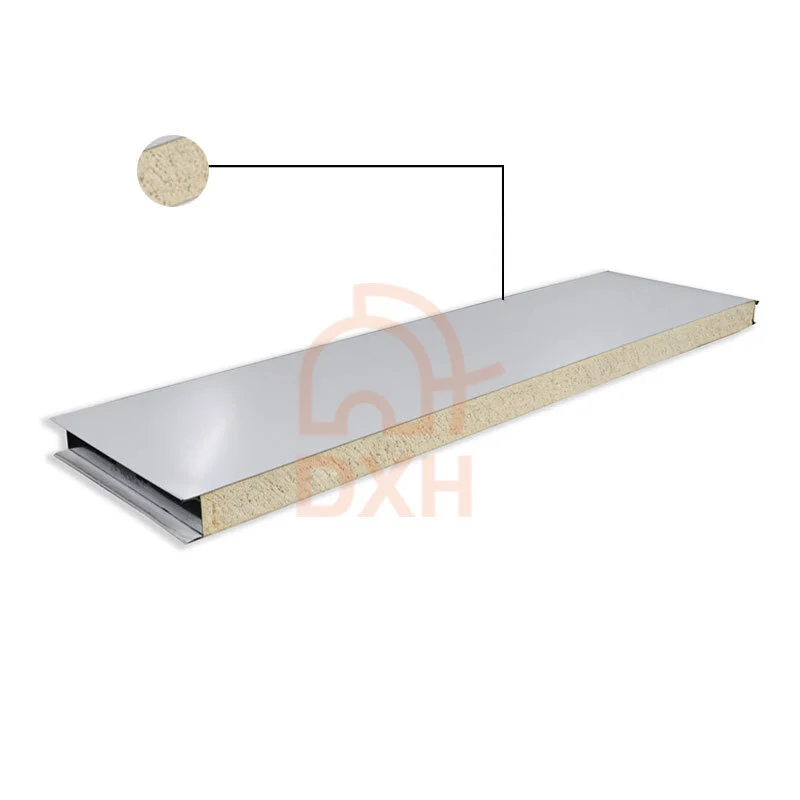

Phenolic Sandwich Panel

Specifications and Properties

|

Width |

950mm, 1150mm |

|

Length |

Customized according to project requirements and transportation conditions |

|

Core Material |

Phenolic Foam |

|

Thickness |

50mm, 75mm, 100mm, 200mm |

|

Core Density |

35 to 100 kg/m³ |

|

Thermal Conductivity |

Usually 0.018 to 0.023 W/m·K |

|

Panel Material |

Color steel, stainless steel |

|

Panel Profiles |

H-panels (flat and profiled), tongue-and-groove, and corrugated panels |

|

Color |

Select according to project requirements |

|

Applications |

External walls, partition walls, interior ceilings, insulation for prefabricated buildings |

Main Benefits of Phenolic Sandwich Panels

Fire Resistance: Phenolic foam is non-flammable, produces minimal smoke and toxic gases during a fire, and meets high fire safety standards.

Thermal Insulation: With a low thermal conductivity (as low as 0.018 W/m·K), these panels provide excellent insulation. They enable thinner panels to deliver the same thermal performance as thicker alternatives.

Lightweight and Easy to Install: Their lightweight feature facilitates easy transportation and installation. Their low density reduces overall building weight and supports quick, efficient assembly.

Structural Strength: The composite structure offers high pressure and shear strength, resisting wind loads and enhancing overall building stability.

Aesthetic Appeal: Available in various textures and colors, phenolic panels can be customized for different architectural styles. They also resist weathering, abrasion, and chemicals.

Phenolic Sandwich Panels: Common Uses

Structural Insulation Panels: Ideal for walls, roofs, and partitions in prefabricated buildings, container homes, and industrial facilities.

Roofing: Used to insulate steel-framed roofs, providing durable, attractive, and thermal insulation.

Special Environments: Suitable for clean rooms, refrigeration facilities, and food or beverage processing environments due to their cleanliness and insulation properties.

Transportation: With high strength-to-weight ratios and fire resistance, they are used in railroads, aircraft, and other transportation modes.

HVAC: Phenolic panels are commonly used in commercial and industrial ductwork, offering lightweight properties, low thermal conductivity, and enhanced fire safety.

Refrigeration: Due to its good temperature control, it is suitable for cold rooms and storage facilities.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China