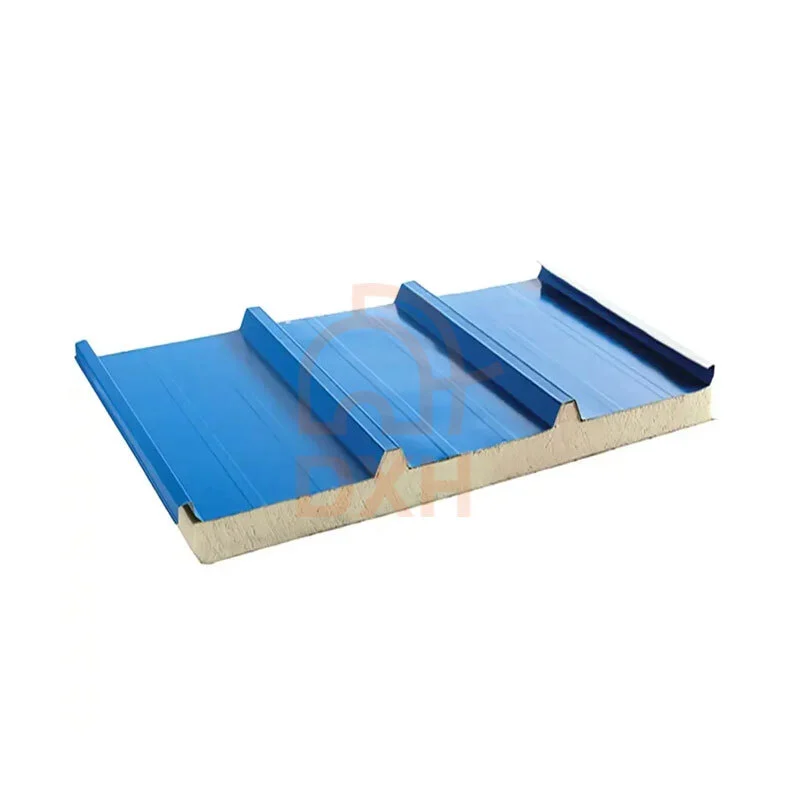

Corrugated Sandwich Panel

Corrugated sandwich panels are composite panels consisting of two layers of corrugated metal, one on top and one on the bottom, with an insulating interlayer in between. The corrugated metal panels are typically made of aluminium, color-coated or galvanized steel, with a wavy (corrugated) structure. The interlayer is commonly made of insulating materials such as polyurethane foam, rock wool, polystyrene (EPS), or magnesium oxysulfide.

This structural design not only ensures the panel's thermal insulation properties but also enhances its mechanical strength and wind resistance, making it a multifunctional sandwich panel that combines thermal insulation and structural support.

Specifications and Features of Corrugated Sandwich Panels

Corrugated Sandwich Panel Structure

The corrugated sandwich panel surface is wavy and formed using a special die. This wavy structure significantly enhances the panel's stiffness and bending resistance, making it exceptionally stable and durable when subjected to wind pressure, weight, and mechanical shock.

Various Insulated Core Material Options

Corrugated sandwich panels come in a variety of insulated core materials, including the following:

Polyurethane Foam Core: Lightweight and highly insulating, it is widely used in industrial plant buildings and cold storage.

Rockwool Core: Excellent fire resistance, suitable for buildings with high fire protection requirements.

EPS Core: Economical and provides excellent thermal insulation.

Magnesium Oxysulfide Core: Inorganic material with outstanding fire and moisture resistance.

Corrugated sandwich panels offer different core materials to meet diverse building requirements, achieving a balance between performance and cost.

High-strength Composite Technology

Corrugated panels are made of advanced cold or hot pressing composite processes to ensure a tight bond between the facesheet and core, preventing delamination. The high overall structural strength prevents deformation and cracking.

Various Sizes and Specifications

Insulated corrugated sandwich panels offer flexible specifications, with customizable lengths, widths, and thicknesses to meet diverse architectural design requirements.

Core Performance Benefits of Corrugated Sandwich Panels

Excellent Thermal Insulation: The core material has a low thermal conductivity, effectively blocking heat conduction. Ensure a pleasant temperature within the building, reducing energy consumption and improving living and working comfort.

High Structural Strength and Strong Wind Pressure Resistance: The corrugated sandwich panel structure increases rigidity, enhancing the panel's load-bearing capacity and wind pressure resistance. This makes it suitable for large-span, heavy-load buildings.

Excellent Fire and Moisture Resistance: Depending on the core material, corrugated sandwich panels can meet different levels of fire protection requirements. The closed-cell core structure effectively resists moisture, extending the building's lifespan.

Lightweight and Easy to Install: Compared to traditional brick-and-concrete buildings, corrugated sandwich panels are much lighter. This makes them easier to transport and install, which helps speed up construction timelines and lowers costs.

Corrosion and Weather Resistance: The panels are treated with a high-performance coating that resists acids and alkalis, making them suitable for a variety of climates.

Energy-Friendly and Energy-Saving: The materials are environmentally friendly, and the production process is low-pollution, meeting green building standards and contributing to sustainable development.

Main Applications of Corrugated Sandwich Panels

Industrial Plants and Warehouses: Corrugated sandwich panels are widely used in the walls and roofs of industrial plants, providing excellent insulation, fire protection, and structural support.

Cold Storage and Cold Chain Logistics: With its excellent thermal insulation and moisture-proof properties, corrugated sandwich panels are an ideal material for cold storage walls and roofs, ensuring stable temperatures throughout the cold chain.

Cleanrooms and Pharmaceutical Workshops: The hygienic and fire-resistant core and panels meet the demands of high-standard cleanroom environments.

Commercial Buildings and Public Facilities: Shopping malls, exhibition halls, stadiums, and other venues utilize corrugated panels to improve energy efficiency and safety.

Residential and Prefabricated Buildings: Corrugated insulated panels are lightweight and offer excellent thermal insulation, making them suitable for modern prefabricated residential construction and promoting the industrialization of the building industry.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China