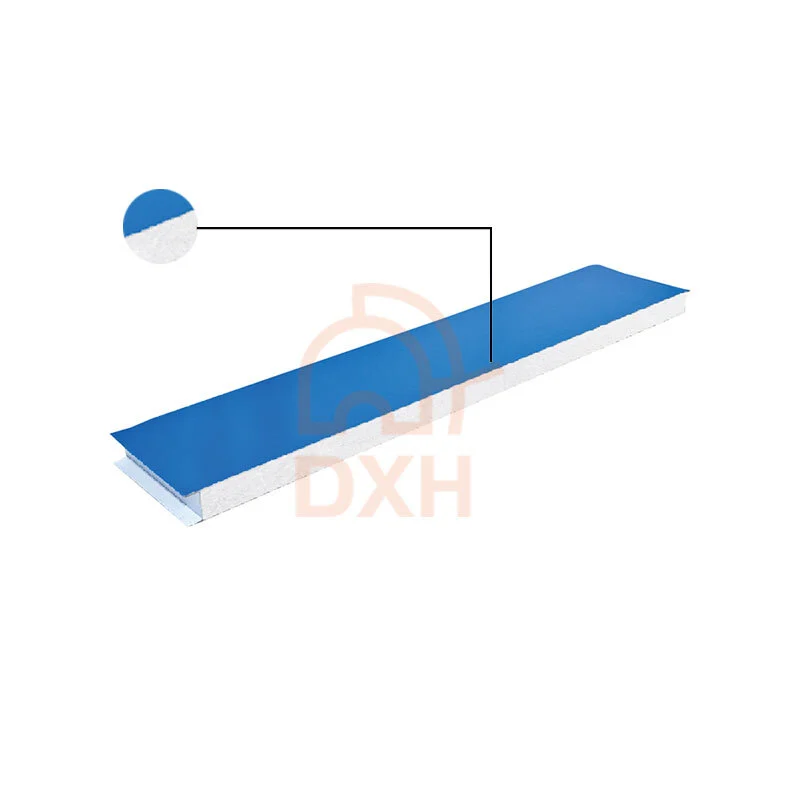

EPS Sandwich Panel

An EPS sandwich panel is a type of lightweight construction sandwich panel made of color-coated steel, galvanized steel, or stainless steel as the surface layer, and polystyrene (Expanded Polystyrene, referred to as EPS) foam board as the core material, bonded together through high-strength adhesive composite hot-pressing.

The EPS sandwich panel is a cost-effective building material that provides perfect thermal insulation performance. It not only shortens the construction timeline but also reduces project costs, making it an essential component of modern light steel structure buildings.

Specifications and Properties

|

Width |

950mm, 1150mm |

|

Thickness |

50mm, 75mm, 100mm |

|

Core Material |

EPS Core |

|

Core Density |

Range from 12 to 24 kg/m³ |

|

Thermal Conductivity |

About 0.038W/m·K |

|

Oxygen Index (Oi) |

34 |

|

Fire Resistance |

Class B1 |

|

Composition of Panel |

Galvanized steel, stainless steel, or colored steel |

|

Shape / Profile |

Tongue-and-groove panels, H-panels |

EPS Sandwich Panel Benefits

Outstanding Thermal Insulation: EPS foam has a thermal conductivity of approximately 0.038 W/m·K, making it an excellent insulator. In comparison to traditional structures, EPS insulated sandwich panels significantly reduce heat transfer between the interior and exterior. This can reduce energy consumption, making them ideal for energy-efficient buildings.

Lightweight Yet Durable: Weighing around 10 kg per square meter—about 1/20 the weight of traditional brick walls—EPS sandwich panels lessen the structural load, making them suitable for a variety of steel frame systems.

Quick Installation and Construction: These sandwich panels are modular and prefabricated in a factory, offering quick transportation and assembly on-site. This efficiency helps save time and labor costs, making them perfect for projects with tight deadlines, such as large industrial plants and temporary structures.

Cost-Effective: Expanded polystyrene sandwich panels are generally less expensive than alternatives such as rock wool and polyurethane due to their simpler manufacturing processes. This helps reduce overall material and construction costs.

Aesthetic and Versatile: The surface layer of these panels can be customized in various colors and profiles to meet specific design requirements, providing buildings with a modern, clean, and uniform appearance.

Recyclable and Reusable: The simple structure of EPS sandwich panels allows for easy disassembly and relocation, making them suitable for modular homes, temporary offices, and warehouses.

Applications of EPS Sandwich Panels

Industrial Facilities: Used as roof, wall, and partition materials offering good insulation, noise reduction, and corrosion resistance, suited for varied manufacturing environments.

Cold Storage and Freezer Warehouses: While EPS insulation isn't as effective as polyurethane, it adequately meets basic insulation needs at a lower cost.

Prefabricated Housing: Ideal for quick and flexible construction of offices, dormitories, and sanitary facilities, with easy disassembly for temporary use.

Clean Rooms and Dust-free Environments: Suitable for low-requirement spaces like food packaging, electronic assembly, and laboratories.

Warehouses and Logistics Centers: Protect goods from temperature fluctuations and ensure optimal storage conditions.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China