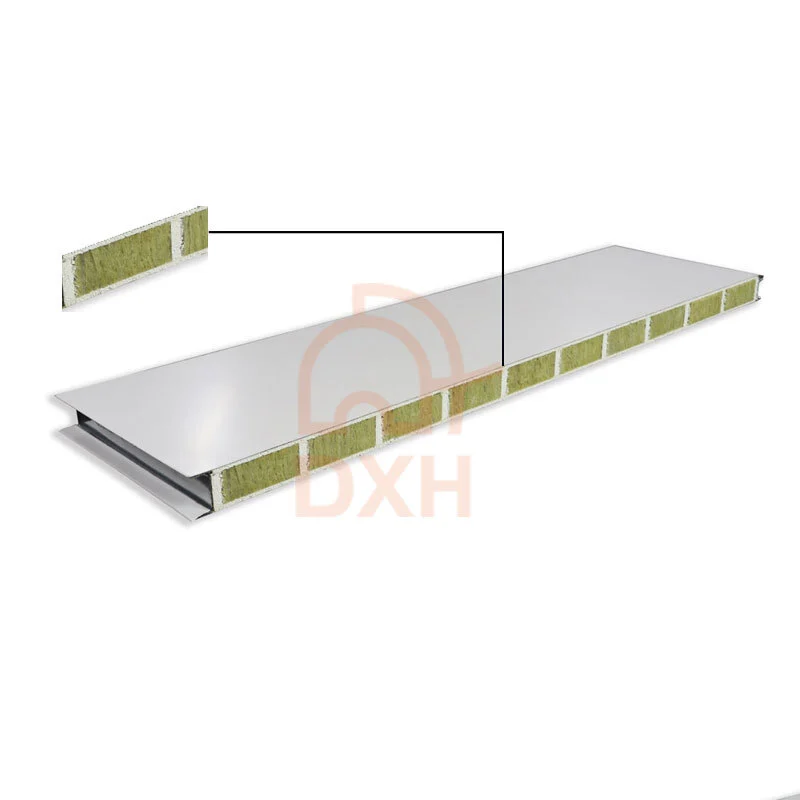

Hollow Glass Magnesium Rockwool Sandwich Panel

Specifications and Properties

|

Core Material |

Hollow Glass Magnesium and Rockwool Core |

|

Width |

950mm, 1150mm |

|

Thickness |

50mm, 75mm, 100mm |

|

Core Density |

0.85-1.5t/m³ |

|

Thermal Conductivity |

As low as 0.043 w/m·k, ensuring good sealing and heat preservation |

|

Fire Resistance |

Class A |

|

Panel Material |

Color Steel |

|

Shape / Profile |

Tongue-and-groove Panels |

Glass Magnesium Rock Wool Sandwich Panel Performance

Fire resistance: The glass magnesium rock wool sandwich panels offer exceptional fire resistance, meeting the highest fire safety standards (Class A). The panels will not ignite or spread flames, making them suitable for public buildings and high-risk environments.

Sound Insulation Performance: The rock wool core material used in these panels has sound-absorbing properties, providing excellent sound insulation and creating a quieter indoor environment.

Thermal Insulation Efficiency: To maintain a comfortable indoor temperature and improve energy efficiency, the stone wool core material provides outstanding thermal insulation performance. By reducing energy consumption and lowering the carbon footprint, these insulated panels effectively minimize heat transfer.

Mechanical Strength: Not only are the glass magnesium rockwool sandwich panels lightweight, but they also have high load-bearing capacity. The panels typically have a width of 950–1150 mm, a customizable length up to 11.8 meters, and a thickness range of 50–100 mm.

Durability: The exterior finish of the sandwich panels can be made from materials such as galvanized steel, stainless steel, or colored steel, ensuring long-lasting durability and corrosion resistance. Furthermore, these core panels feature high density and excellent impact resistance.

Environmental Protection and Health: These glass magnesium rock wool sandwich panels are non-toxic, odorless, and free of radioactive contamination. Its corrosion resistance, moisture resistance, antibacterial properties, and insect resistance reduce maintenance costs and extend its service life.

Industry Applications

Hollow glass magnesium rockwool sandwich panels are widely used across various industries due to their excellent fire resistance, thermal insulation, soundproofing, durability, and ease of installation. The following are typical applications:

Cleanrooms: Typically used in industries with strict fire safety and cleanliness requirements for walls and ceilings, such as pharmaceuticals, biotechnology, electronics, and food processing.

Commercial and Office Buildings: Suitable for building envelopes, such as exterior walls and roofs, as well as interior partitions where sound insulation and fire safety are critical.

Food Industry Facilities: Applied in areas prioritizing thermal insulation and hygiene, such as food processing plants and cold storage facilities.

Industrial Buildings: Used as roofs and wall panels for factories, warehouses, workshops, and logistics centers. Its fire-resistant and thermal insulation properties make it an ideal choice for industrial environments where safety and temperature control are critical.

Prefab and Modular Structures: Sandwich panels are popular due to their easy installation and versatile qualities. They are suitable for various applications, including container homes, temporary accommodations, remote offices, and emergencies.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China