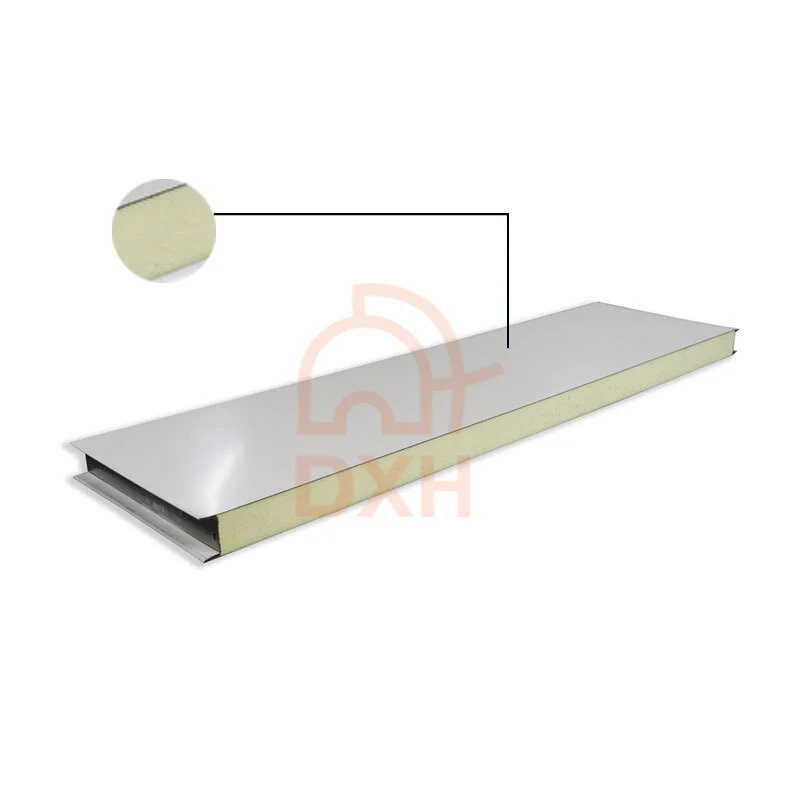

PU Sandwich Panel

PU sandwich panels are high-performance insulated structural elements composed of a core made of polyurethane foam. This core is sandwiched between two layers of either galvanized or color-coated steel sheets, which are bonded through cold-pressing or hot-pressing processes.

These polyurethane materials are known for their excellent insulation properties, thermal resistance, lightweight design, high strength, and structural load-bearing capabilities. As a result, they are widely used in various applications, including building walls and roofs, cold chain logistics, industrial facilities, and cleanrooms.

Specifications and Properties

|

Core Material |

Polyurethane Foam Core |

|

Width |

950mm, 1150mm |

|

Thickness |

50mm, 75mm, 100mm |

|

Core Density |

Ranges from 35-45 kg/m³ |

|

Thermal Conductivity |

Range of 0.020-0.028 W/(m.k) |

|

Fire Resistance |

Class B |

|

Panel Material |

Color steel, stainless steel, or aluminum alloy |

|

Shape / Profile |

Tongue-and-groove board |

|

Adhesive |

High-strength, environmentally friendly adhesive is used to bond the core material to the panel securely |

Main Advantages of Polyurethane Sandwich Panels

Excellent Thermal Insulation Performance: The low thermal conductivity of polyurethane rigid foam enables sandwich panels to deliver significantly better thermal insulation than traditional materials at the same thickness, thereby greatly reducing energy consumption in buildings and equipment.

Light and High Strength: PU sandwich panels are not only lightweight, which simplifies transportation and installation, but they also boast outstanding compressive and bending strength, allowing them to be used directly as structural elements in building envelopes.

Self-extinguishing: Made with flame-retardant materials that comply with national Class B fire safety standards, PU sandwich panels offer good fire resistance.

Weather Resistance and Longevity: The panel coatings resist corrosion, fading, and aging. Besides, the core material remains stable and resistant to deformation, ensuring long-term performance.

Easy and Quick Installation: Polyurethane panels have precise dimensions and flexible installation options. The prefab and modular design can be quickly assembled, reducing construction time, lowering difficulty, and decreasing labor costs.

Environmental and Energy Saving: Made from eco-friendly materials, these sandwich panels generate minimal pollution during production, meet green building standards, and help reduce carbon emissions.

Applications of PU Sandwich Panels

Roof and Wall Cladding: PU panels are commonly used in the exterior walls and roofs of industrial, commercial, and residential structures because of their outstanding thermal insulation capabilities, durability against the elements, and straightforward installation process.

Refrigeration and Freezing Rooms: PU insulated panels maintain a constant low temperature, making them ideal for refrigeration rooms, freezers, and cooling facilities in the food and pharmaceutical industries.

Cleanrooms and Controlled Environments: PU sandwich panels are used in industries like pharmaceuticals, electronics, and food processing to create sealed, hygienic spaces that prevent contamination.

Prefab and Modular Structures: Polyurethane-insulated sandwich panels are lightweight and durable, enabling quick assembly of portable cabins, on-site offices, modular buildings, and temporary structures.

Agricultural Buildings: Used to isolate farm warehouses and storage facilities, protecting crops, livestock, and equipment from temperature fluctuations, moisture, pests, and chemicals.

Industrial Facilities: Such as warehouses, factories, and logistics hubs, utilize polyurethane sandwich panels to create sturdy, energy-efficient buildings that can withstand harsh environments while providing insulation and soundproofing performance.

Electrical and Maritime Industries: Polyurethane sandwich panels can also serve as electrical insulation materials and as lightweight, insulated structural components in the manufacturing of vehicles and ships.

FAQs About PU Insulated Sandwich Panels

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China