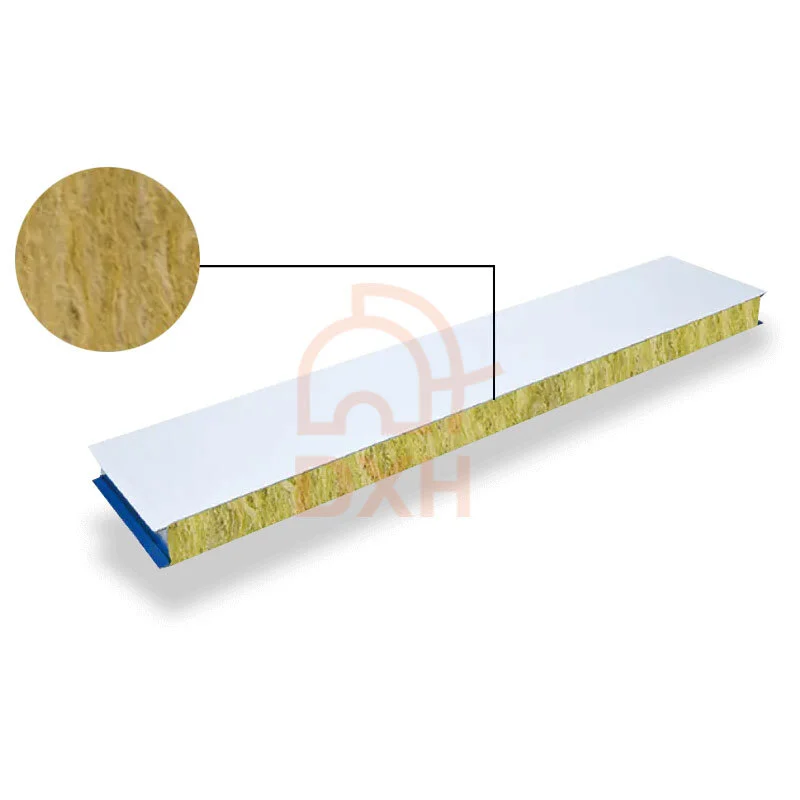

Rockwool Sandwich Panel

Specifications and Properties

|

Core Material |

Rock Wool |

|

Width |

950mm, 1150mm |

|

Thickness |

50mm, 75mm, 100mm, 125mm, 150mm, and 200mm |

|

Core Density |

Ranges from 80 to 150 kg/m³ |

|

Thermal Conductivity |

Around 0.035 W/m·K, providing effective insulation |

|

Fire Resistance |

Class A |

|

Panel Material |

Color-coated steel or galvanized steel is used, with the surface coated with multiple layers to provide corrosion resistance and wear resistance |

|

Shape / Profile |

Tongue-and-groove board, corrugated sandwich panel (flat plate, pressed type) |

|

Acoustic Insulation |

Rock wool fibers have a dense, porous structure and good sound absorption properties, effectively reducing noise |

|

Durability |

The panels are dimensionally stable, resistant to weather, moisture, and temperature variations, ensuring long-lasting performance |

Performance Advantages of Rockwool Sandwich Panels

Fire Performance: The stone wool core material is an inorganic non-combustible material capable of withstanding temperatures above 1,200°C. It does not ignite and does not emit toxic fumes, making it essential for achieving Class A fire resistance ratings.

Thermal Insulation: Rock wool has a low thermal conductivity, effectively reducing heat transfer. This ensures stable indoor temperatures while reducing energy consumption for air conditioning and heating, meeting the requirements of energy-efficient buildings.

Moisture-Resistant and Corrosion-Resistant Performance: The dense structure of the rock wool core material prevents water absorption. Combined with corrosion-resistant coated metal panels, it effectively prevents moisture penetration, adapts to various complex environments, and extends the service life of the panels.

Sound Insulation and Noise Reduction Performance: The porous fiber structure of stone wool provides excellent sound absorption, effectively reducing noise in industrial plants and public buildings, and enhancing indoor environmental comfort.

High Strength and Durability: The stone wool sandwich panel is designed with composite processing, resulting in a strong and durable structure. Its perfect compression and impact resistance make it suitable for a variety of applications.

Environmental Safety: Rock wool sandwich panels are environmentally safe and free from harmful substances because they are made from natural, recyclable materials. Additionally, improvements in energy efficiency in buildings help reduce their environmental footprint.

Applications of Rock Wool Sandwich Panels

Industrial Buildings: Widely used for thermal insulation in the walls and roofs of industrial buildings, meeting multiple requirements such as fire resistance, thermal insulation, and corrosion resistance.

Public Buildings: Used in the walls and roofs of large shopping malls, sports arenas, exhibition halls, and other public facilities to enhance building safety and energy efficiency.

Cold Storage and Cold Chain Logistics: The thermal insulation and heat insulation properties of rock wool sandwich panels make them an ideal choice for the walls and roofs of cold storage facilities, ensuring stable temperatures in cold chain environments.

Clean Rooms and Pharmaceutical Workshops: Their fire-resistant, dust-proof, and sound-insulating properties meet the stringent requirements of clean rooms and high-standard purification workshops.

Petrochemical and High-Temperature Environments: Rock wool sandwich panels excel in high-temperature resistance, making them suitable for buildings in special high-temperature environments such as petrochemical facilities.

Key Points for the Installation of Rock Wool Sandwich Panels

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China