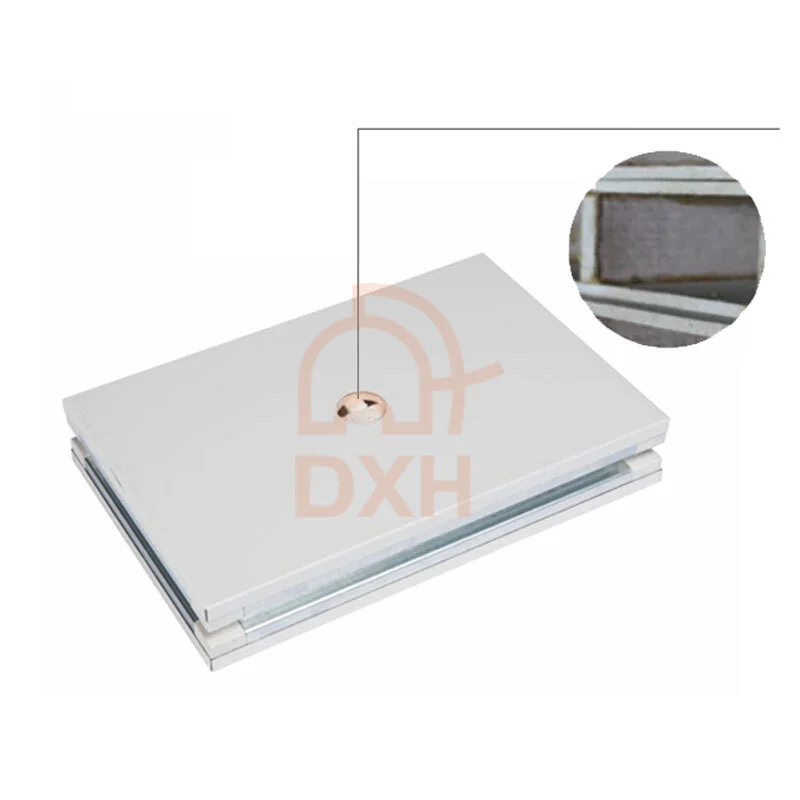

Handmade Hollow Glass Magnesium Sandwich Panel

Specifications

|

Core Material |

Hollow Glass Magnesium |

|

Thickness |

50mm, 55mm, 60mm, 75mm, 100mm |

|

Width |

900mm, 980mm, 1150mm, 1180mm. Non-standard panels in any width. |

|

Length |

Custom manufacturing is available upon request (general length ≤ 6000mm). |

|

Panel Thickness |

0.18mm -1.2mm (Commonly used color-coated/fluorocarbon/aluminized zinc/antistatic steel sheets. Double-sided or single-sided magnesium oxide + steel plate combination options are available upon request.) |

|

Edge Sealing |

Aluminum alloy profiles are used for edge sealing on all four sides, increasing the overall structural sealing and deformation resistance. |

|

Adhesive |

Uses an environmentally friendly structural adhesive to ensure a firm bond between the panel and the inner frame. |

|

This handmade hollow glass magnesium panel not only surpasses traditional rock wool and paper honeycomb sandwich panels in physical properties but also has significant advantages in environmental protection, fire resistance, durability, and ease of construction, making it a component of modern clean room spaces. |

|

Handmade Hollow Glass Magnesium Sandwich Panel Performance

Lightweight Structure: The hollow structure significantly reduces the weight of the panels, making handling and installation more efficient. At the same time, a high-strength frame is formed by steel keel support, making it resistant to deformation or cracking even under significant external impact.

Flame Retardant Performance: The material used in handmade hollow magnesium panels is an inorganic, non-combustible material, classified as Class A, meeting fire safety standards.

Moisture and Corrosion Resistant: It possesses excellent water resistance, moisture resistance, and corrosion resistance, showing no deformation after immersion in water for 8 hours.

Due to a new type of building material that integrates fire resistance, moisture resistance, lightweight properties, high strength, environmental friendliness, and durability. The handmade hollow magnesium sandwich panels are gradually becoming the preferred solution for clean rooms, food factories, laboratories, the medical industry, prefabricated buildings, and modular structures.

Installation Process of Hand-Made Hollow Magnesium Sandwich Panels

Hand-made hollow core magnesium oxide sandwich panels utilize a dry construction method, resulting in fast installation and a clean environment. The typical installation steps are as follows:

1. Measurement and Layout: Locate the foundation lines according to the construction drawings.

2. Keel Installation: Install the ground rails, wall columns, and top keel according to the panel dimensions.

3. Panel Cutting: It can cut the panels as needed to avoid waste at the edges.

4. Panel Placement: Vertically insert the panels into the keel frame, adjusting verticality and joints.

5. Fixing and Reinforcing: Reinforce and fix the panels using self-tapping screws or aluminum profile clamps.

6. Joint Sealing: Seal the joints using silicone or foam strips.

Due to their flexible dimensions and customizable processing, they are suitable for construction in various non-standard shapes and spatial scenarios.

Frequently Asked Questions

Xunqing Rd No.639, Taoyuan Town, Wujiang District, Suzhou City,

Jiangsu Province, China